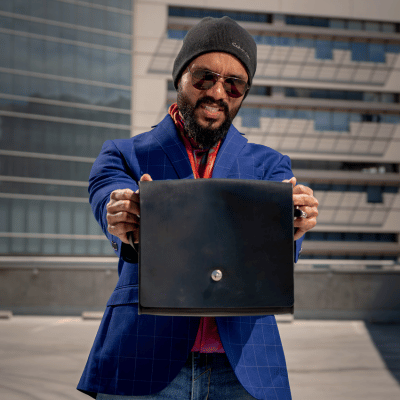

Our Quality

Fewer Seams

While our thread boasts exceptional quality, it inherently falls short of the sheer strength found in a solid piece of premium American leather. Recognizing this, we strategically minimize seams in our designs to reduce stress points. By prioritizing a minimalistic approach, we aim to enhance the overall durability and longevity of our products.

Hand-stitching

Stitching isn't just a detail to us; it's a fundamental element that defines the quality and construction of our products.

In our craft, we employ saddle stitching, a time-honored technique named after its preference among saddlemakers. The choice is deliberate—considering the resilience required for horse saddles that endure wear and tear over decades, we recognize its enduring quality.

Our saddle-stitching method involves using a single, long strand of three-strand cord thread, crafted from wax-coated polyester (known for its exceptional strength). The meticulous process entails weaving the thread back and forth, creating a robust and overlapping pattern around the seam. To reinforce the integrity of the stitch, we backstitch at least four times through the same holes. Finally, we meticulously burnish over the ends, ensuring a finish that resists unraveling. This commitment to saddle stitching reflects our dedication to crafting products with enduring strength and quality.

Hand-punching

Hand-punching is an integral aspect of our craftsmanship, echoing our commitment to meticulous detail in the creation of leather goods. We opt for a hands-on approach, ensuring that each hole is carefully punched with precision. This manual technique not only adds a personal touch to every product but also allows for a level of control and accuracy that machines cannot replicate. The artistry involved in hand-punching contributes to the overall uniqueness of our leather goods, enhancing their character and ensuring that every piece is a testament to the dedication invested in its creation.

Leather

WICKETT & CRAIG

Founded in 1867, Wickett & Craig is a world-premiere vegetable tannery. Their hides are a byproduct of the beef and dairy industry and would otherwise be wasted. A labor-intensive method that requires skilled workers, veg-tanning is a natural, eco-friendly process that produces durable, exquisite, sustainable luxury leathers recognized for their depth of color and rich patina. Simply put their leathers not only endure, they get better with age.

USA

BRASS HARDWARE

BUCKLEGUY

Buckleguy is a USA based company operating in Massachusetts with manufacturing in China. Brass is under 90ppm lead content which meets the requirements set out by California’s Prop 65, as well as the European REACH standards.

USA/China/Hong Kong

FASTENERS

SCHAEFFERTEC GMBH

RoHS and Reachcompliant secure fasteners from Schaeffertec. Lots of women’s bags use magnetic fasteners that are easy to use but not particularly secure. These take a bit more care to use and are incredibly secure. “Environment and health go hand in hand. Whether waste water disposal, material recycling or waste disposal: all production steps are planned and carried out in accordance with the requirements of German standards. We also ensure that our end products take important health aspects into account. Our products comply with the European REACH directive and are also RoHS compliant.” - Schaeffertec

Germany

Thread

JULIUS KOCH

This is asynthetic waxed braided polyester thread from Julius Koch. While it’s not a natural product, I use it because of the durability and longevity. Part of sustainability is making something that will last. Natural alternatives do not resist abrasion or wear like this does. As a company they take measures towards sustainability and use ethical manufacturing practices.

Germany

ENVIRONMENT

Chemicals

To minimize the chemical impact, sustainable luxury vegetable-tanned leather is used exclusively. Chrome tanning is used by the bulk of the industry because it is faster and cheaper, though it damages the environment and is harmful to workers.

Vegetable tanning uses plant materials which is slower, more costly, and at the same time, better for the environment and the humans processing the leather.

Climate Impact

While the beef and dairy industries contribute to CO2 in our environment, using hides that are otherwise waste and will need to be disposed of in some other way minimizes further damage.

What about "vegan" leather? While there are a few exceptions, these are products that incorporate a great deal of plastic while be marketed as good for the environment and animal friendly.